Study on bullet proof mechanism of UD non weft cloth

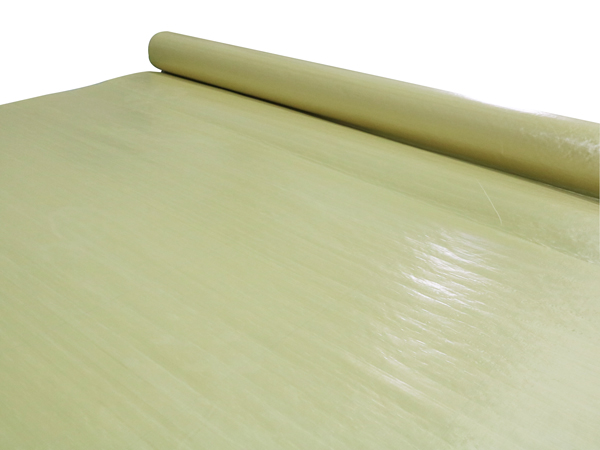

A single fiber or bundle of fibers can not play the role of bulletproof. Only by arranging and integrating the fibers according to certain rules can we effectively resist the attack of bullets or fragments. At present, there are two main ways to integrate fibers regularly: woven fabric and weft free fabric. Woven fabric is woven by loom, while weft free fabric is made by special unidirectional composite process. The fiber of woven fabric is damaged during weaving. In addition, when the strain wave propagates on the fabric surface, the connection point of the fiber reflects and superimposes the strain wave, which is easy to cause excessive elongation and fracture of the fiber, and its bulletproof performance is affected. Weft free fabric can eliminate the fiber buckling in the fabric, has excellent physical and mechanical properties, good kinetic energy absorption and no "secondary killing effect". Therefore, it has good bulletproof performance and is the form of bulletproof fabric in the world

Aramid nonwovens are mainly composed of two components: high performance aramid fiber and resin adhesive.

According to the penetration of the projectile into the aramid weft free composite target, it can be seen that when the projectile hits the target, a radial vibration wave is generated in the impact point area due to the impact of the projectile, and the vibration wave propagates outward in two directions; 1 is to propagate along the axial direction of the fiber with continuous pulses. When reaching the staggered point of the fiber, the vibration wave is diffused on many fibers through the interaction between the fibers and the matrix resin, and the energy of the wave is absorbed over a considerable area; 2 is the longitudinal propagation of tension wave along the target. The tension wave generates continuous reflection between the non weft cloth and the matrix resin interface, which changes the pressure into tensile stress. When the tensile stress value is greater than the bonding strength between the fiber and the matrix resin, it will lead to the fracture of the fiber and the resin matrix and absorb part of the energy of the projectile. Due to the different strain wave velocities between the fiber and the matrix material, the fiber is "pulled out" from the matrix material, and the work done by the fiber "pulled out" will absorb part of the energy of the projectile. Secondly, with the deeper penetration of the projectile, the fiber is subjected to tensile deformation and local deformation of the target. The kinetic energy of the projectile is transformed into the elastic potential energy of the fiber and the tangential work done by the local deformation of the target. When the strain of the fiber is greater than its strain, the fiber breaks. Fibrillation occurs after fiber fracture, which further consumes the energy of the projectile. If the projectile still has excess kinetic energy, it will further penetrate the next layer until the kinetic energy of the projectile is completely consumed.

National service telephone:189-0510-0000

Company address:No. 111, Fenghuang South Road, Yandu District, Yancheng City, Jiangsu Province

手机站二维码